Tobacco Barns of the Pee Dee, a photography exhibit that traveled through the Pee Dee in 2009, was created by Benton Henry, Dr. Wink Prince and Bruce Douglas. This same trio came together again in 2012 to produce The Great Harvest: Remember Tobacco in the Pee Dee, a book about the region's tobacco culture.

With the recent release of The Great Harvest, now seems like the perfect time to revisit Tobacco Barns of the Pee Dee. Below is the online version of the exhibit. The photographs were taken by Benton Henry. The text was written by Dr. Wink Prince. The exhibit was curated by Bruce Douglas.

Tobacco Barns of the Pee Dee

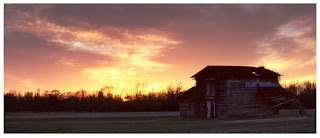

This is a two-store packhouse at sunset. After the cured tobacco was removed from the barn, it went to the packhouse for further processing and storage. Workers removed the leaves from the sticks, sorted them by color, and tied them into bundles called hands. The hands of tobacco were bulked together to await transport to market.

This is a two-store packhouse at sunset. After the cured tobacco was removed from the barn, it went to the packhouse for further processing and storage. Workers removed the leaves from the sticks, sorted them by color, and tied them into bundles called hands. The hands of tobacco were bulked together to await transport to market. This tobacco barn is typical of curing barns built from the 1940s through the 1960s. Curing barns were usually constructed of homegrown lumber, covered with sheathing, and roofed with tin. The standard size was 20 square feet with five rooms of tier poles for hanging sticks of tobacco leaves.

This tobacco barn is typical of curing barns built from the 1940s through the 1960s. Curing barns were usually constructed of homegrown lumber, covered with sheathing, and roofed with tin. The standard size was 20 square feet with five rooms of tier poles for hanging sticks of tobacco leaves. In the 1970s, tobacco farmers began curing their crop in fuel-efficient, all-metal bulk barns. Traditional barns like this one fell into disrepair. No longer in use, owners have little incentive to invest in maintaining them. Hurricanes have taken their toll as well.

In the 1970s, tobacco farmers began curing their crop in fuel-efficient, all-metal bulk barns. Traditional barns like this one fell into disrepair. No longer in use, owners have little incentive to invest in maintaining them. Hurricanes have taken their toll as well. A barn full of leaf tobacco could be cured in four to five days using artificial heat. Bottom leaves, known as lugs, were cured first. The middle leaves, known as cutters, were next. The uppermost leaves, known as tips, were cured last. In the Pee Dee, the harvesting/curing season usually lasted from late June into August.

A barn full of leaf tobacco could be cured in four to five days using artificial heat. Bottom leaves, known as lugs, were cured first. The middle leaves, known as cutters, were next. The uppermost leaves, known as tips, were cured last. In the Pee Dee, the harvesting/curing season usually lasted from late June into August. A stringing shed sheltered work outside the bar. Workers fastened green tobacco leaves to wooden sticks with cotton string. The sticks were hung above flues that ran along the floor of the barn. Early barns heated with brick furnaces were fueled with wood cut from the owner's forest. in the late 1950s, kerosene and propane gas replaced wood as curing fuels.

A stringing shed sheltered work outside the bar. Workers fastened green tobacco leaves to wooden sticks with cotton string. The sticks were hung above flues that ran along the floor of the barn. Early barns heated with brick furnaces were fueled with wood cut from the owner's forest. in the late 1950s, kerosene and propane gas replaced wood as curing fuels. The rustic character of the lumber on this barn testifies to its origins. These boards were likely sawn from pines that grew on this farm. The remnants of the pine forest can be seen in the in the distance. The stringing shed has been removed from this barn.

The rustic character of the lumber on this barn testifies to its origins. These boards were likely sawn from pines that grew on this farm. The remnants of the pine forest can be seen in the in the distance. The stringing shed has been removed from this barn. This interior view shows the beams that hled the tobacco sticks in the barn. In the bottom right, you can see the sticks that the leaves were strung on. The round metal objects are burners. In this case, propane ws used to create heat for curing. Earlier barns would have used wood fires.

This interior view shows the beams that hled the tobacco sticks in the barn. In the bottom right, you can see the sticks that the leaves were strung on. The round metal objects are burners. In this case, propane ws used to create heat for curing. Earlier barns would have used wood fires. In the 1950s and 1960s, one curing barn was needed for every six acres of tobacco. Approximately 90 percent of the weight of green tobacco was lost in curing. One acre yielded about 2000 pounds of cured leaf.

In the 1950s and 1960s, one curing barn was needed for every six acres of tobacco. Approximately 90 percent of the weight of green tobacco was lost in curing. One acre yielded about 2000 pounds of cured leaf. A few curing barns were built of concrete blocks. The insulating characteristtics of blocks saved fuel and justified their higher cost. Some block built barns have been converted to other uses. Others will stand as permanent reminders of the past.

A few curing barns were built of concrete blocks. The insulating characteristtics of blocks saved fuel and justified their higher cost. Some block built barns have been converted to other uses. Others will stand as permanent reminders of the past. This multi-purpose barn served as a tobacco packhouse, stable, and storage shed. Cured tobacco was kept upstairs, while horses and mules were kept downstairs. Eventually, tracotrs and implements replaced the draft animals. The truck is a Chevrolet, circa 1950.

This multi-purpose barn served as a tobacco packhouse, stable, and storage shed. Cured tobacco was kept upstairs, while horses and mules were kept downstairs. Eventually, tracotrs and implements replaced the draft animals. The truck is a Chevrolet, circa 1950. A dilapidated tobacco barn sits abandoned and surrounded by cotton, where tobacco once grew. As tobacco farming has declined, cotton has regained popularity. This scene has become commonplace on many Pee Dee farms.

A dilapidated tobacco barn sits abandoned and surrounded by cotton, where tobacco once grew. As tobacco farming has declined, cotton has regained popularity. This scene has become commonplace on many Pee Dee farms.

No comments:

Post a Comment